Engineering kunststoffen

For this project, the focus was on plastics, specifically material and manufacturing knowledge. My task was to design a meal box for the back of a bicycle. This involved injection molding and vacuum forming.

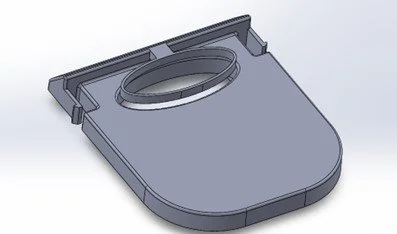

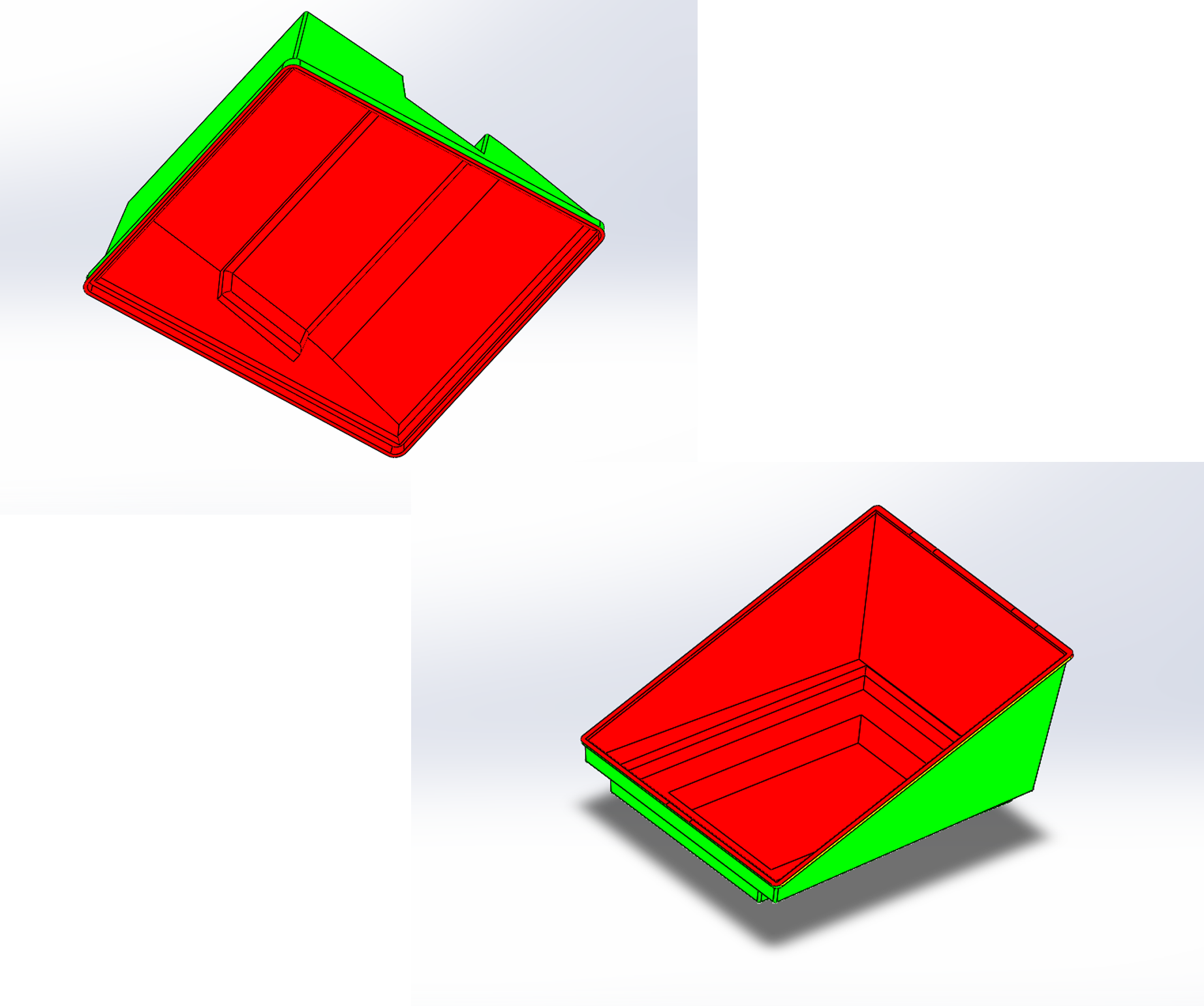

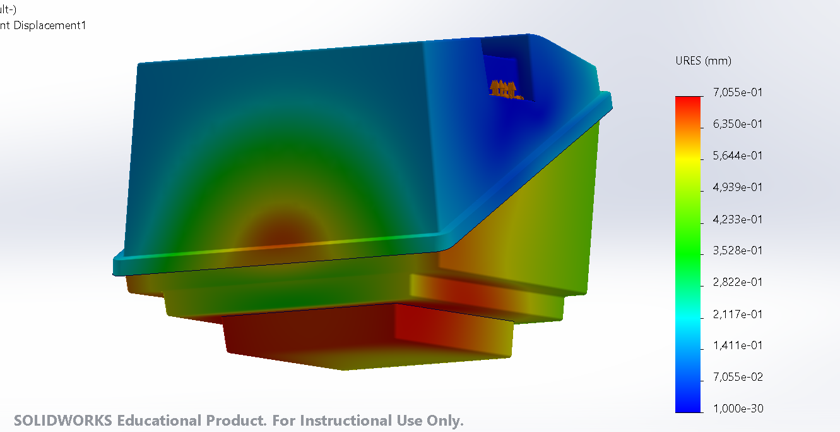

As the end result, I developed a vacuum-formed meal box made of ABS. The challenge was to make it water- and windproof, while still making the box easy to open and close. Moreover, the box can be operated with one hand. For attachment to the luggage carrier, I designed a clamp produced via injection molding. This clamp is made of POM so that it can perform the function of a spring.

Learned and applied skills:

- Solution-oriented design

- Discussing mold and process costs

- Unloading design (injection & vacuum forming)

- Solidworks simulations

- Solidworks

- Solidworks Visualize

- Extensive material and production knowledge about plastics